- Burst disks for 1800 psi tanks are not easy to find in the Scuba world. I've seen them in the Paintball suppliers but they look a little different... Like the disk is integral to the nut or something. Are these usable on my 3/8" Scuba valve burst disk ports?

- Bryan's got 3/8" burst disks rated 2250 psi. I take it these are for tanks with 2250 psi stamped on them? Or, do they burst at 2250 psi and they're for use on 1800 psi tanks?

- SurfLung

- Master Diver

- Posts: 1763

- Joined: Sat Jan 01, 2011 2:03 pm

- First Name: Eben

- Location: Alexandria, MN

- Contact: Website

Questions About Burst Disks

SurfLung

The Freedom and Simplicity of Vintage Equipment and

Vintage Diving Technique are Why I Got Back Into Diving.

The Freedom and Simplicity of Vintage Equipment and

Vintage Diving Technique are Why I Got Back Into Diving.

- luis

- VDH Moderator

- Posts: 1747

- Joined: Thu Jun 30, 2005 9:28 pm

- First Name: Luis

- Location: Maine

Re: Questions About Burst Disks

The rupture pressure of a burst disc should be 5/3 of the stamped pressure (the same as the test pressure for a 3AA tank). The tolerance range should be +0, -10%.

That means for a 1800 psi tank the burst disc should let go at 3000 psi (+0, -10%).

For a 2250 psi cylinder the burst disc should release at 3750 psi.

I don't know if the paintball burst disc will work on a scuba cylinder valve. I would think that if the threads are the same and it seals in the same manner it would, but I don't have direct experience with it.

That means for a 1800 psi tank the burst disc should let go at 3000 psi (+0, -10%).

For a 2250 psi cylinder the burst disc should release at 3750 psi.

I don't know if the paintball burst disc will work on a scuba cylinder valve. I would think that if the threads are the same and it seals in the same manner it would, but I don't have direct experience with it.

Luis

Buceador con escafandra autónoma clásica.

Buceador con escafandra autónoma clásica.

- SurfLung

- Master Diver

- Posts: 1763

- Joined: Sat Jan 01, 2011 2:03 pm

- First Name: Eben

- Location: Alexandria, MN

- Contact: Website

Re: Questions About Burst Disks

- Thanks Luis. I've got these little 1800 psi twin tanks and would like to replace the Burst disks. From your reply, I definitely need to go with the 1800 psi ones. Here are some pictures of 1800 psi paintball tank burst disks:

- None of the pictures and information I have found shows them with a separate disk and washer. And the bottoms don't look as flat as Scuba Burst Disks. They DO have the same 3/8" thread. As you say, getting these to seal may be a trick.

- None of the pictures and information I have found shows them with a separate disk and washer. And the bottoms don't look as flat as Scuba Burst Disks. They DO have the same 3/8" thread. As you say, getting these to seal may be a trick.

SurfLung

The Freedom and Simplicity of Vintage Equipment and

Vintage Diving Technique are Why I Got Back Into Diving.

The Freedom and Simplicity of Vintage Equipment and

Vintage Diving Technique are Why I Got Back Into Diving.

- antique diver

- Master Diver

- Posts: 2210

- Joined: Sun Dec 10, 2006 12:50 pm

- First Name: Bill

- Location: North-Central Texas

Re: Questions About Burst Disks

Those should work. The originals were typically in three pieces, but these "modular" replacements came out later and have worked in some of my valves just fine. Don't let the shape worry you... give one a try and see what happens.

The older I get the better I was.

- SurfLung

- Master Diver

- Posts: 1763

- Joined: Sat Jan 01, 2011 2:03 pm

- First Name: Eben

- Location: Alexandria, MN

- Contact: Website

Re: Questions About Burst Disks

- Thanks Antique. I was hoping to hear from someone who had tried them. Did you do anything to seal them... Like a rubber washer or O-Ring?

SurfLung

The Freedom and Simplicity of Vintage Equipment and

Vintage Diving Technique are Why I Got Back Into Diving.

The Freedom and Simplicity of Vintage Equipment and

Vintage Diving Technique are Why I Got Back Into Diving.

- luis

- VDH Moderator

- Posts: 1747

- Joined: Thu Jun 30, 2005 9:28 pm

- First Name: Luis

- Location: Maine

Re: Questions About Burst Disks

I would definitely not used a rubber O-ring or gasket. Rubber O-rings need to be enclosed in a defined volume with a known amount of compression (roughly about 10 to 20% max, I can't remember the preferred compression). That is why they have to be designed to fit in an O-ring groove or similar type cavity with a precise amount of compression. If a rubber O-ring is over compressed (or crushed) it will loose its elasticity and eventually fail.

For a gasket like this you would use a harder plastic like Teflon, nylon, or similar.

The sealing could be also be accomplished with soft metals like a brass or copper seal.

In this case it looks like it is designed to be a brass seal. Brass or copper seals are very common. The 3 piece US Divers and Sherwood manifolds use brass metal to metal seals. The bonnet on many scuba valves also use metal to metal copper to brass seals.

You could also try to re-use the original nylon seal or just try the metal to metal seal. Either one should work, but the nylon seal should require lower torque to create a good seal.

For a gasket like this you would use a harder plastic like Teflon, nylon, or similar.

The sealing could be also be accomplished with soft metals like a brass or copper seal.

In this case it looks like it is designed to be a brass seal. Brass or copper seals are very common. The 3 piece US Divers and Sherwood manifolds use brass metal to metal seals. The bonnet on many scuba valves also use metal to metal copper to brass seals.

You could also try to re-use the original nylon seal or just try the metal to metal seal. Either one should work, but the nylon seal should require lower torque to create a good seal.

Luis

Buceador con escafandra autónoma clásica.

Buceador con escafandra autónoma clásica.

- antique diver

- Master Diver

- Posts: 2210

- Joined: Sun Dec 10, 2006 12:50 pm

- First Name: Bill

- Location: North-Central Texas

Re: Questions About Burst Disks

A metal to metal seal is reasonable to expect, and fairly commonly used, with the soft metals like brass and copper. If that doesn't work for you with a reasonable amount of torque, I may have some copper or nylon washers that would do it. Let me know.SurfLung wrote:- Thanks Antique. I was hoping to hear from someone who had tried them. Did you do anything to seal them... Like a rubber washer or O-Ring?

BTW, sometimes a little silicone lube on the sealing surfaces and the threads will let them slide together and seal with less torque applied. Also may help from galling the sealing surfaces. I have done that many times when a seal was difficult to get between two metals. On the other hand, Tapered pipe threads are still best sealed with Teflon tape wraps.

The older I get the better I was.

- Drado

- Master Diver

- Posts: 682

- Joined: Mon Feb 07, 2011 6:11 am

- First Name: Eduardo

- Location: Manila, Philippines

Re: Questions About Burst Disks

From Eben's photo, it looks like the unplated contact surface of the assembly is a different material. Could it be an integrated crush washer?

_______________________________

Ed

Ed

- antique diver

- Master Diver

- Posts: 2210

- Joined: Sun Dec 10, 2006 12:50 pm

- First Name: Bill

- Location: North-Central Texas

Re: Questions About Burst Disks

Seems likely to me as well.Drado wrote:From Eben's photo, it looks like the unplated contact surface of the assembly is a different material. Could it be an integrated crush washer?

The older I get the better I was.

- SurfLung

- Master Diver

- Posts: 1763

- Joined: Sat Jan 01, 2011 2:03 pm

- First Name: Eben

- Location: Alexandria, MN

- Contact: Website

Re: Questions About Burst Disks

This TOTALLY BLOWS!

- I keep my vintage equipment up to date and good as new... Don't want people thinking I dive "old crap".

- So I got my beautiful yellow USD Twin 38s hydro tested and inspected... And they passed with flying colors. Next I wanted to update the burst disks from the old lead plug type to modern. BIG OOPS! The only Burst disks I could find in these tanks 1800 PSI range are from Paintball companies. The above discussion looks at the possibility of using these in my Scuba tank valves.

- First thing I noticed is that the original lead slug plugs also had a burst disk. Since these tanks hadn't had a hydro since they left the factory in 1961, I'm assuming they were installed that way by USD. But you can see why it looks like they were hard plugged instead of working as a safety release.

(Left-Orig burst disk and lead plug-nuts. Center-Thread length comparison. Right- Blown paint ball burst disk compared to a new one and copper washer spacers I used to get them to seal.)

- So at this point I was thinking, "I'm really doing a good job to put the correct pressure, function burst disks on these valves". But I could't get them to seal. I finally figured out that the threaded section was too short and they weren't bottoming out. How could I get them to touch bottom and seal?

- I put in a couple of copper washers as spacers so that the paintball burst disks could bottom out and seal. Eureka... I thought. I squirted soapy water on them and watched as I filled the tanks. No leaks. Then...

- POW!... . At about 1000 psi, one of these paintball burst disks let go and the roar of escaping air scared the crap out of me. This is the second time a burst disk has blown on me. The first was with those twin 42 Sportsways tanks. That one was a brand new 2250 psi Scuba burst disk. I ended up just putting the originals back in and used those tanks all summer.

- Once again, I'm going to have to put the original system back in these Twin 38s... My confidence is totally blown (good pun). Replacements are most likely being installed wrong by me or the wrong part (paintball version). But if I can't get the correct part as a newly manufactured item, the "old crap" part really is the best part I can use... Both for safety and practicality.

- I keep my vintage equipment up to date and good as new... Don't want people thinking I dive "old crap".

- So I got my beautiful yellow USD Twin 38s hydro tested and inspected... And they passed with flying colors. Next I wanted to update the burst disks from the old lead plug type to modern. BIG OOPS! The only Burst disks I could find in these tanks 1800 PSI range are from Paintball companies. The above discussion looks at the possibility of using these in my Scuba tank valves.

- First thing I noticed is that the original lead slug plugs also had a burst disk. Since these tanks hadn't had a hydro since they left the factory in 1961, I'm assuming they were installed that way by USD. But you can see why it looks like they were hard plugged instead of working as a safety release.

(Left-Orig burst disk and lead plug-nuts. Center-Thread length comparison. Right- Blown paint ball burst disk compared to a new one and copper washer spacers I used to get them to seal.)

- So at this point I was thinking, "I'm really doing a good job to put the correct pressure, function burst disks on these valves". But I could't get them to seal. I finally figured out that the threaded section was too short and they weren't bottoming out. How could I get them to touch bottom and seal?

- I put in a couple of copper washers as spacers so that the paintball burst disks could bottom out and seal. Eureka... I thought. I squirted soapy water on them and watched as I filled the tanks. No leaks. Then...

- POW!... . At about 1000 psi, one of these paintball burst disks let go and the roar of escaping air scared the crap out of me. This is the second time a burst disk has blown on me. The first was with those twin 42 Sportsways tanks. That one was a brand new 2250 psi Scuba burst disk. I ended up just putting the originals back in and used those tanks all summer.

- Once again, I'm going to have to put the original system back in these Twin 38s... My confidence is totally blown (good pun). Replacements are most likely being installed wrong by me or the wrong part (paintball version). But if I can't get the correct part as a newly manufactured item, the "old crap" part really is the best part I can use... Both for safety and practicality.

SurfLung

The Freedom and Simplicity of Vintage Equipment and

Vintage Diving Technique are Why I Got Back Into Diving.

The Freedom and Simplicity of Vintage Equipment and

Vintage Diving Technique are Why I Got Back Into Diving.

- luis

- VDH Moderator

- Posts: 1747

- Joined: Thu Jun 30, 2005 9:28 pm

- First Name: Luis

- Location: Maine

Re: Questions About Burst Disks

I will strongly recommend against reusing the old lead plug (or a even a new old stock lead plug with burst disc). The burst disc was part of the original combination.

I have personally seen them release and they are just like a lead bullet. Now that you have removed it, if you re-install it, it has a higher chance of releasing at a lower pressure. Even if I knew it was in perfect condition, I would never use a lead plug burst disc.

If you can't find a scuba 1800 (designed to release at 3000 psi), I would use one for a 2250 psi cylinder (designed to release at 3750 psi).

The burst disc is intended to protect you in case of a fire. Just make sure your cylinders are never in a fire situation with the higher release burst disc.

I have personally seen them release and they are just like a lead bullet. Now that you have removed it, if you re-install it, it has a higher chance of releasing at a lower pressure. Even if I knew it was in perfect condition, I would never use a lead plug burst disc.

If you can't find a scuba 1800 (designed to release at 3000 psi), I would use one for a 2250 psi cylinder (designed to release at 3750 psi).

The burst disc is intended to protect you in case of a fire. Just make sure your cylinders are never in a fire situation with the higher release burst disc.

Luis

Buceador con escafandra autónoma clásica.

Buceador con escafandra autónoma clásica.

- captain

- Plank Owner

- Posts: 1440

- Joined: Mon Jul 04, 2005 11:32 am

- Location: LaPlace, LA

Re: Questions About Burst Disks

You may be able to remove the bust disc itself from the unified paintball retainer and use it with a regular scuba retainer or melt the lead out of the original plug and fill the cavity with melted wax or silicone grease. I usually use silicone grease to keep salt water away from the disc.

Captain

- SurfLung

- Master Diver

- Posts: 1763

- Joined: Sat Jan 01, 2011 2:03 pm

- First Name: Eben

- Location: Alexandria, MN

- Contact: Website

Re: Questions About Burst Disks

- Captain, near as I can tell, the paintball unit isn't actually a "disk". It looks more like a one piece brass cup. The blown one has the bottom of the cup blown out.

- Luis, thanks for the advice. I see Bryan has 2015 psi burst disks I can try. I think one of these is what let go on my 42s. I think I had tightened it too much and squished the nylon washer enough to constrict the center hole. This might have happened with the copper washers I used on the paintball units.

- Luis, thanks for the advice. I see Bryan has 2015 psi burst disks I can try. I think one of these is what let go on my 42s. I think I had tightened it too much and squished the nylon washer enough to constrict the center hole. This might have happened with the copper washers I used on the paintball units.

SurfLung

The Freedom and Simplicity of Vintage Equipment and

Vintage Diving Technique are Why I Got Back Into Diving.

The Freedom and Simplicity of Vintage Equipment and

Vintage Diving Technique are Why I Got Back Into Diving.

- luis

- VDH Moderator

- Posts: 1747

- Joined: Thu Jun 30, 2005 9:28 pm

- First Name: Luis

- Location: Maine

Re: Questions About Burst Disks

Over tightening the disc can affect its release pressure. I can see it being a particular problem if you use a washer that is stiffer than the intended plastic one. It could easily damage the disc (or the base of the cup).

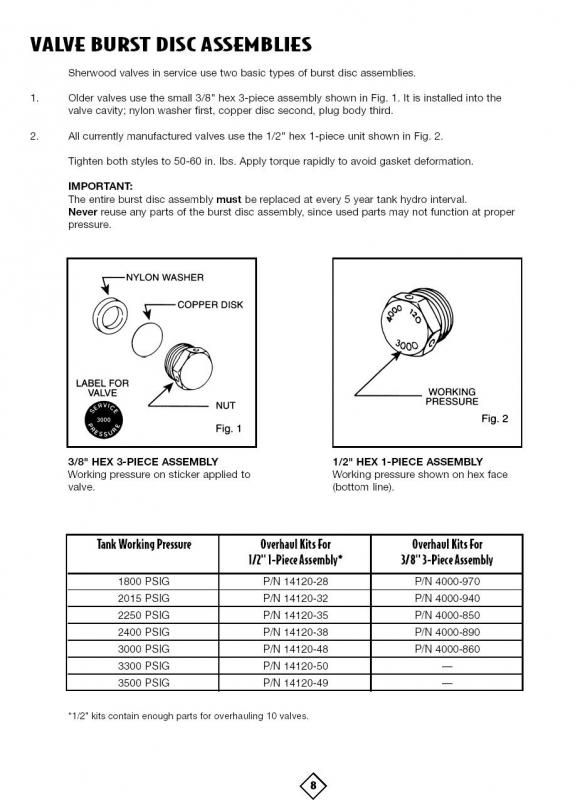

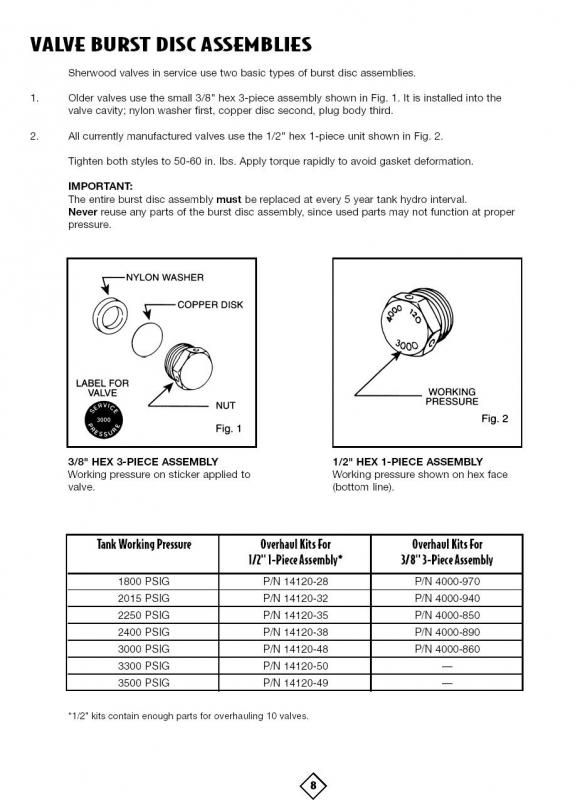

In the Sherwood manual it says to torque the burst disc to 50 – 60 in*lbs

I would get the 2015 psi ones (Sherwood P/N 4000-940), but Bryan may be able to special order the 1800 psi type (Sherwood P/N 4000-970).

The new burst disc plugs are far superior to the single outlet plugs.

The single outlet plug (even without the lead plug) will shoot the air in one direction creating a single jet nozzle. If the burst disc lets go, it can tip over a standing tanks or make a tank that is laying down tumble out of control.

The jet is small enough that the tank can be held, but if it starts tumbling around it can cause some damage.

Note: I saw a number of burst discs let go when I worked at DSC (in PR) back in the 70’s. What I hated the most was when the burst disc let go while filing the tank inside the water bath. There was no way out of getting totally soaked.

At least our water tank restrained the cylinder from moving around too much since it was a narrow and heavy aluminum container.

Now-days, the plugs are always supplied with the burst disc and they are supposed to be replaced together as a pair. The plug is the cutter for the discs. If they are not replaced as a match pair, it was found that the release pressure became less predictable. Which could in part, explain some of the premature burst disc releases we used to experience. I am sure corrosion in the Caribbean was another factor.

The new plugs have three outlets to balance the thrust from the gas flow and (more important) they will capture the pieces from the ruptured disc to avoid injury.

AFAIK, the old style plugs are required to be replaced with the new style according to the CGA (Compress Gas Association) codes (for all the reasons mentioned above), but I don’t have copies of the particular CGA document that referred to this subject. CGA documents are very expensive and I only have a few.

In practical terms, there is no one enforcing the valve burst disc requirements (unless you have a knowledgeable LDS) so the CGA code is not as big of deal, as for example the hydro requirements. But, there are other good reasons to follow the codes.

Here is page from the Sherwood valve manual that may be usefull:

In the Sherwood manual it says to torque the burst disc to 50 – 60 in*lbs

I would get the 2015 psi ones (Sherwood P/N 4000-940), but Bryan may be able to special order the 1800 psi type (Sherwood P/N 4000-970).

The new burst disc plugs are far superior to the single outlet plugs.

The single outlet plug (even without the lead plug) will shoot the air in one direction creating a single jet nozzle. If the burst disc lets go, it can tip over a standing tanks or make a tank that is laying down tumble out of control.

The jet is small enough that the tank can be held, but if it starts tumbling around it can cause some damage.

Note: I saw a number of burst discs let go when I worked at DSC (in PR) back in the 70’s. What I hated the most was when the burst disc let go while filing the tank inside the water bath. There was no way out of getting totally soaked.

At least our water tank restrained the cylinder from moving around too much since it was a narrow and heavy aluminum container.

Now-days, the plugs are always supplied with the burst disc and they are supposed to be replaced together as a pair. The plug is the cutter for the discs. If they are not replaced as a match pair, it was found that the release pressure became less predictable. Which could in part, explain some of the premature burst disc releases we used to experience. I am sure corrosion in the Caribbean was another factor.

The new plugs have three outlets to balance the thrust from the gas flow and (more important) they will capture the pieces from the ruptured disc to avoid injury.

AFAIK, the old style plugs are required to be replaced with the new style according to the CGA (Compress Gas Association) codes (for all the reasons mentioned above), but I don’t have copies of the particular CGA document that referred to this subject. CGA documents are very expensive and I only have a few.

In practical terms, there is no one enforcing the valve burst disc requirements (unless you have a knowledgeable LDS) so the CGA code is not as big of deal, as for example the hydro requirements. But, there are other good reasons to follow the codes.

Here is page from the Sherwood valve manual that may be usefull:

Luis

Buceador con escafandra autónoma clásica.

Buceador con escafandra autónoma clásica.

- SurfLung

- Master Diver

- Posts: 1763

- Joined: Sat Jan 01, 2011 2:03 pm

- First Name: Eben

- Location: Alexandria, MN

- Contact: Website

Re: Questions About Burst Disks

- Thanks Luis, that's all very helpful. I had not thought to ask Bryan to special order it and will try that.

- And, yes that makes sense that over tightening could pre-cut or weaken the blow-out to let go at a lower pressure. I'll see about getting a small torque wrench to get them properly tight in the future.

- I'm also going to do some checking to see if there is a way to make the paintball units work correctly for Scuba. I was thinking to call a paintball service shop and see if they might already have a solution.

- I found a service reference for paintball burst disks at http://www.ninjapaintball.com/documents ... 0Guide.pdf.

- If I do anymore experimenting with paintball burst disks, I'm going to wear my ear protectors and be ready for it... So at least I'm not so totally shocked if one lets go!

- And, yes that makes sense that over tightening could pre-cut or weaken the blow-out to let go at a lower pressure. I'll see about getting a small torque wrench to get them properly tight in the future.

- I'm also going to do some checking to see if there is a way to make the paintball units work correctly for Scuba. I was thinking to call a paintball service shop and see if they might already have a solution.

- I found a service reference for paintball burst disks at http://www.ninjapaintball.com/documents ... 0Guide.pdf.

- If I do anymore experimenting with paintball burst disks, I'm going to wear my ear protectors and be ready for it... So at least I'm not so totally shocked if one lets go!

SurfLung

The Freedom and Simplicity of Vintage Equipment and

Vintage Diving Technique are Why I Got Back Into Diving.

The Freedom and Simplicity of Vintage Equipment and

Vintage Diving Technique are Why I Got Back Into Diving.

Who is online

Users browsing this forum: No registered users and 118 guests