Page 1 of 1

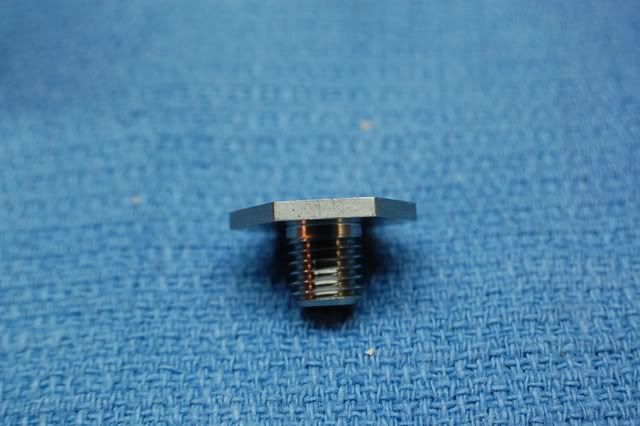

Scubapro MK 5 Swivel Nut

Posted: Wed Jul 25, 2012 8:24 am

by Bryan

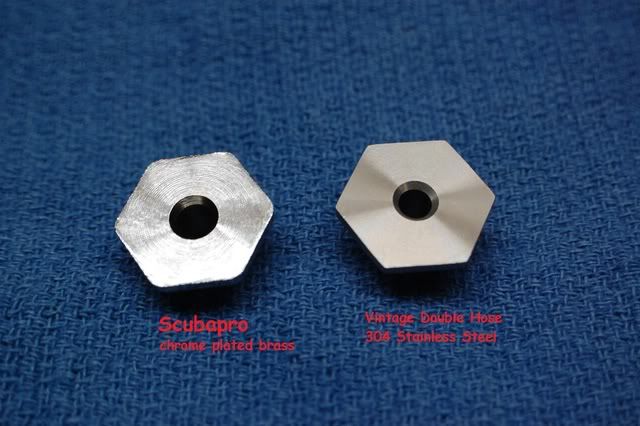

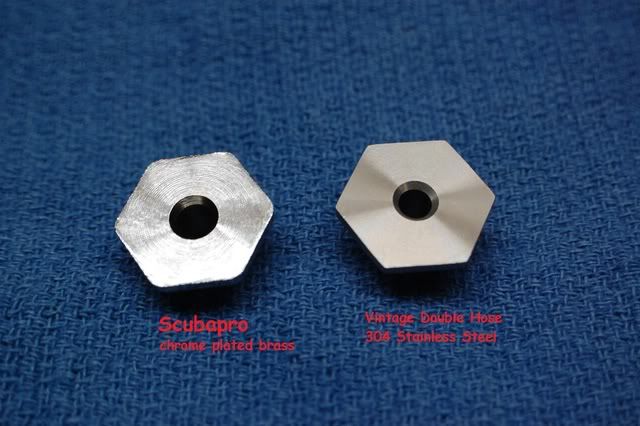

Made an agreement with a small machine shop in Bloomington Indiana to reproduce the swivel nut for MK 5's in stainless. The originals were made in chrome plated brass and are easy to break if too much torque is used.

These should be in stock by the time we get back from Portage. Sign up for the VDH newsletter and be the 1st to know when they hit the store shelf.

Re: Scubapro MK 5 Swivel Nut

Posted: Wed Jul 25, 2012 5:59 pm

by Drado

Excellent!

There's gonna be more than a few people happy with that news

Re: Scubapro MK 5 Swivel Nut

Posted: Fri Aug 03, 2012 2:38 pm

by Bryan

They are in route to me now. Not sure if I'll have them in the store before Portage or not. Watch for the newsletter in your E-mail

Re: Scubapro MK 5 Swivel Nut

Posted: Wed Aug 08, 2012 3:46 pm

by Bryan

Stainless swivel nuts will be in the store when I return from portage. Newsletter subscribers watch your inbox.

Re: Scubapro MK 5 Swivel Nut

Posted: Thu Aug 16, 2012 10:16 am

by couv

Well done Bryan and Luis.

A while back we were discussing the proper torque for this retainer. SP shows a torque of 35-45 inch pounds with an * that points to an engineering note to replace the brass retainer with a SS; however the note makes no differentiation in the torque value for brass vs. SS.

The MK10 has two torque values, 35 in lbs for brass and 70 in lbs for SS.

So Luis, should we bump up the torque for the SS (if so how much) or will 35in lbs be enough load to keep it secure?

Thanks,

Couv

Re: Scubapro MK 5 Swivel Nut

Posted: Thu Aug 16, 2012 7:58 pm

by luis

Hi Couv,

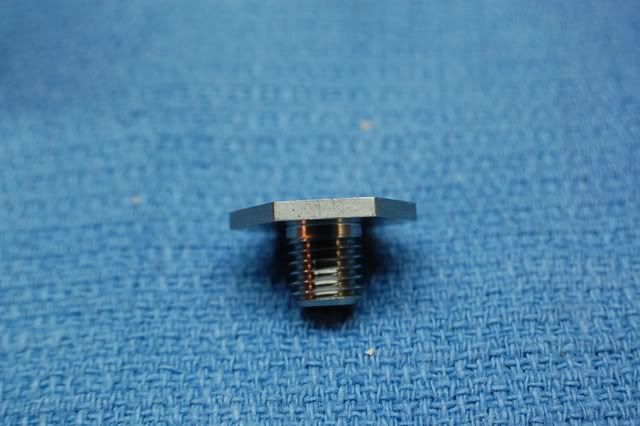

In this application the 5/16-24 bolt is not clamping anything. What I mean is that there is no clamping force needed to clamp parts together.

The head of the bolt is just a stop and it is not trying to clamp parts together to keep them from sliding. It actually has a low friction washer under the head to allow it to slide.

The only purpose for the torque it to keep the bolt from unscrewing and backing out.

As long as you don’t go crazy rotating the swivel or expose the regulator to a high vibration environment, there are only minimal forces trying to unscrew the bolt. Also regular inspection should expose a loose screw. Look at the gap or any change in the amount of play of the swivel.

I looked at some of my old calculation, and based on that I would keep the torque on the MK-5 SS bolt between 35 to 40 in lb.

I would assume that Scubapro was not addressing the torque on the brass bolt since it is telling the customer not to use them.

I don’t know the actual size of the bolt on the newer regulators (Mk-10 and forward), but my understanding is that they are larger. The strength area is a function of the diameter square. Therefore, it doesn’t take much of an increase in bolt diameter to substantially increase its strength.

Re: Scubapro MK 5 Swivel Nut

Posted: Sun Aug 26, 2012 9:43 pm

by Bryan

If you are new to working on MK5/10 first stages there are several specialty tools that make the job much easier.

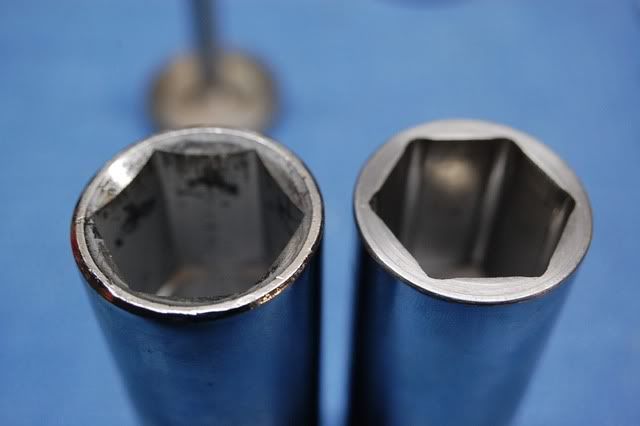

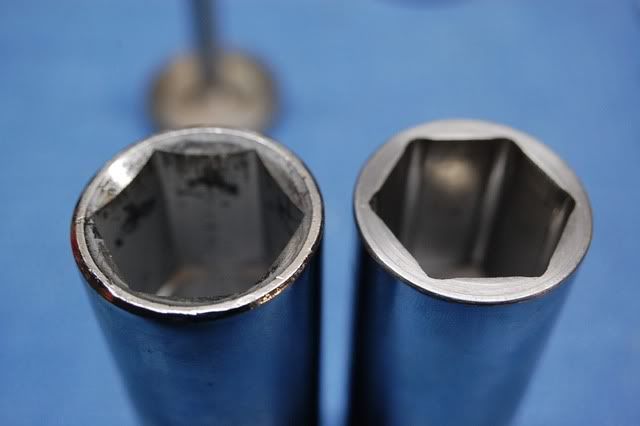

If you are trying to remove, install and torque the swivel retainer nut it can be difficult or impossible to do using a regular 11/16" socket.

The nut itself is very thin by design for clearance. Most out of the standard out of the box sockets have a flare around the outer edge to help guide themselves onto bolts which are much taller than the Scubapro swivel retainer nut and most will either slip or not work at all for this application where getting the torque is important.

Herman can do wonders with a stock 11/16" socket and will make one for you that will hold the nut securely and allow the proper torque to be applied without slipping.

Re: Scubapro MK 5 Swivel Nut

Posted: Wed Aug 29, 2012 10:05 pm

by EHowe

Just bought my first MK5/R109. What other must/should have tools should I be looking for? Herman mentioned a bullet tool a while back and I'm sure a spanner would be helpful. Seems A little more specialized than my Conshelf.

Re: Scubapro MK 5 Swivel Nut

Posted: Thu Aug 30, 2012 6:56 am

by Herman

I would suggest at least a couple of pin spanners (one "A or C" style and one "B or D" style on this MMC page

http://www.mcmaster.com/#pin-spanner-wrenches/=j2lpn1 ) a bullet tool and a modified socket for the swivel nut. The bullet tool is fairly simple,just a piece polished wood,plastic or metal that is the same diameter as the piston stem that has one end pointed and the other end is small enough to slip into the stem of the piston. I prefer a softer material like delrin or nylon to prevent damage to the piston lip but most use brass. I am going to be making a couple of MK-5/109 tools in the near future- materials are on the way. I will have the socket above and a nifty 109 lever adjusting tool will be available in a couple of weeks. I was not going to make bullet tools but if some of you want them, I can make a few of those too.

Re: Scubapro MK 5 Swivel Nut

Posted: Thu Aug 30, 2012 7:10 am

by Bryan

http://www.scubatools.com/p-470-scubapr ... brass.aspx

http://www.scubatools.com/p-458-scubapr ... minum.aspx

As Herman said, he will have some great Scubapro tools soon. I'm trying to get him to expand his product line but there are only so many hours in the day.

I have all the Scubapro specialty tools made by Scuba Tools and many original Peter Built (Pete Wolfinger) tools as well. Some of them are very specialized and must be used to service the regulator properly. Others can be worked around with similar tools. I'm considering renting the specialty ones for a nominal fee plus shipping.

If you are going to work on Scubapro stuff I'd get your own basic tools and let me know if you need one of the specialized model specific tools.

Re: Scubapro MK 5 Swivel Nut

Posted: Fri Aug 31, 2012 1:24 pm

by EHowe

Thanks guys. Been very happy with the tools I've gotten from Herman in the past. I will definitly be watching for those so you can put me down as a buyer. Herman If you made up a bullet tool I'd get that too.